Product Description

Galvanized 6000# 2x3 Straight Trailer Axle Hub Face Over 89".

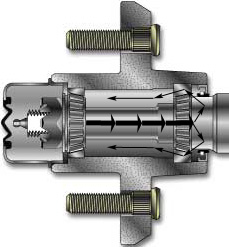

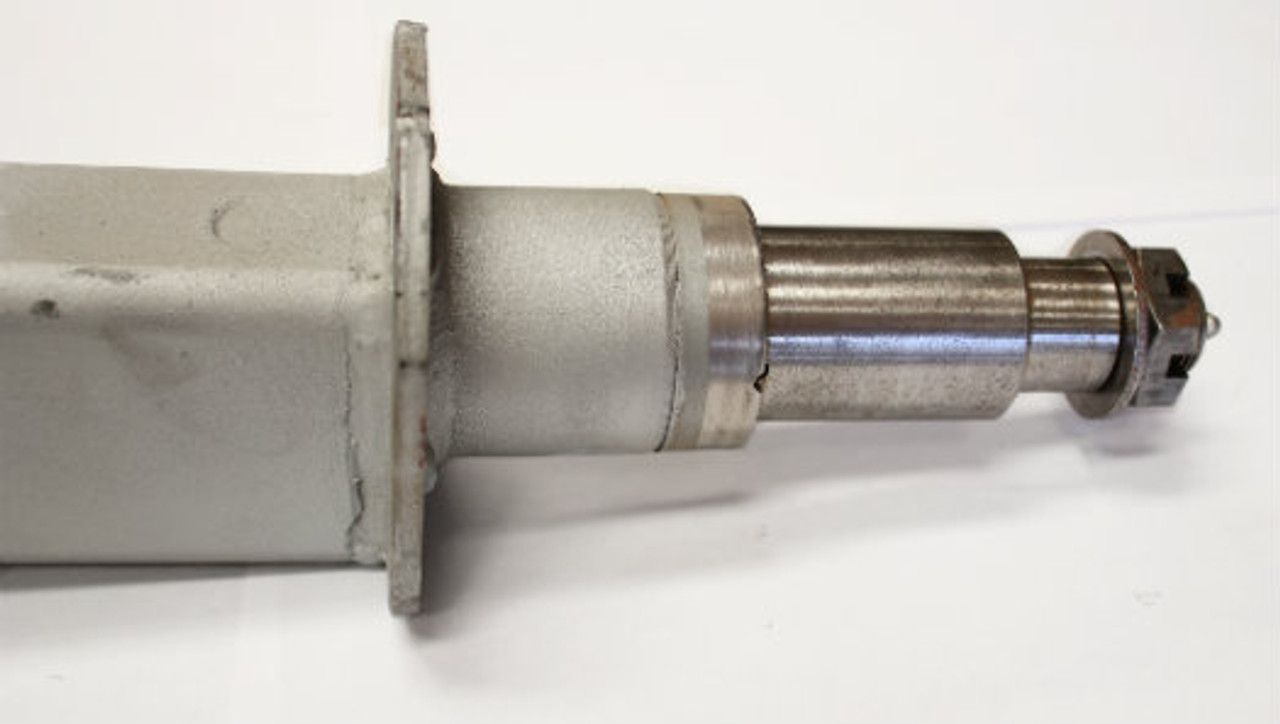

This trailer axle features the Spindle-lube ® hub lubrication system which allows you to grease the hubs without removing them from the axle. Unlike a bearing 'buddy', which only pumps grease into the front of the hub and can often be over-pumped and blow the grease seal, Spindle-lube trailer axles pump the grease to the back of the hub by a hole bored through the length of the spindle where it enters the hub just before the rear seal. The grease then moves forward filling the hub and bearings completely. When re-packing hubs with these trailer axles, the old grease will come out of the front of the hubs, around the tip of the grease gun. The grease should continue to be pumped until new grease comes out of the front of the hub. Then just replace the rubber plug into the dust cap and you are ready to go!!

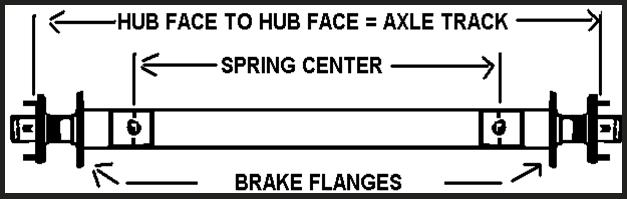

This custom galvanized boat trailer axle is manufactured to the customer's track and spring center measurements. The track measurement is taken from the FACE of one hub (where the hub and the rim touch) to the FACE of the other hub. The spring center measurement is from center to center of the leaf springs on the trailer. [TIP - measure from the inside of one spring to the outside of the other spring for an exact spring center measurement.] There must be a minimum difference of 13" between the track and the spring center measurements in order for this axle to be built. Axles require a Minimum 20 Business Days for Fabricationbusiness days for fabrication (excluding holidays and weekends)

**THIS IS A NON-REFUNDABLE ITEM**

**Flat Rate Ground Shipping is only for the contiguous / lower 48 states U.S **

ITEM INCLUDES:

1 - Axle

2 - 1" castle nuts.

2 - 1" Tab lock washers.

2 - Spindle-lube dust caps with rubber plugs.

Trailer Axle Includes:

1 - Axle

2 - 1" castle nuts.

2 - 1" Tab lock washers.

2 - Spindle-lube dust caps with rubber plugs.

HOW TO MEASURE A TRAILER AXLE

MEASUREMENT # 1 = AXLE TRACK

MEASUREMENT # 2 = SPRING CENTER

How to Order an Axle

- Select your axle part number from the axle charts. Be sure to identify axle over or axle under springs when you select your part number. You want an axle that is similar to the one currently under the trailer to avoid any problems with clearance.

- We need your axle track measurement. This measurement is taken from the face of one hub to the face of the other hub. DO NOT measure from the back of the hub or brake flange as this will provide an incorrect track measurement.

MEASURE HUB FACE TO HUB FACE ONLY.

- The only other measurement needed is the spring center. This measurement is from the center of one spring to the center of the opposite spring. This is a very important measurement as this is where your springs will sit on the axle.

- (Quick Tip) An easy way to measure your spring center is to hook a tape on the outside of one spring and measure to the inside of the opposite spring. This will give you an accurate measurement.

How does the Spindle Lube Spindle Work?

This trailer axle features the Spindle-lube ® hub lubrication system which allows you to grease the trailer hubs without removing them from the axle. Unlike a bearing 'buddy', which only pumps grease into the front of the trailer hub and can often be over-pumped and blow the grease seal, Spindle-lube trailer axles pump the grease to the back of the trailer hub by a hole bored through the length of the trialer spindle where it enters the hub just before the rear seal. The grease then moves forward filling the trailer hub and trailer bearings completely. When re-packing hubs with these trailer axles, the old grease will come out of the front of the hubs, around the tip of the grease gun. The grease should continue to be pumped until new grease comes out of the front of the hub. Then just replace the rubber plug into the dust cap and you are ready to go!!